Hydrogen is considered a potential clean energy source due to its abundance and the fact it only produces water when burned. It holds promise for a variety of applications similar to fossil fuels. However, transforming hydrogen into a viable fuel alternative involves several challenges due to the different methods of production, each with its own environmental impacts represented by a color spectrum ranging from gray (least eco-friendly) to green (most desirable). Green hydrogen, produced from renewable electricity, is the ideal as it offers a powerful, clean fuel source, but is still not widely produced because of current cost and inefficiency issues.

Several startups, like H2Pro and CZero, are striving to innovate in the hydrogen production industry. H2Pro employs a novel technique to efficiently produce hydrogen by leveraging heat rather than power to separate oxygen, significantly lowering costs. Meanwhile, CZero utilizes a method called turquoise hydrogen, which removes solid carbon from natural gas, offering a low-emission solution but still faces cost challenges. The sector's success hinges on reducing production costs to make hydrogen a credible competitor against traditional fossil fuels.

Main takeaways from the video:

Please remember to turn on the CC button to view the subtitles.

Key Vocabularies and Common Phrases:

1. combustible [kəmˈbʌstəbəl] - (adjective) - Capable of catching fire and burning; easily ignitable. - Synonyms: (flammable, incendiary, ignitable)

There are some things where you just need good, old fashioned combustible fuel.

2. carbon capture [ˈkɑrbən ˈkæptʃər] - (noun) - A technology aimed at capturing the carbon dioxide emissions produced from the use of fossil fuels in electricity generation and industrial processes, preventing CO2 from entering the atmosphere. - Synonyms: (emissions reduction, CO2 removal, carbon sequestration)

Blue hydrogen is gray hydrogen, but with carbon capture instead.

3. electrodes [ɪˈlɛktroʊdz] - (noun) - Conductors through which electricity enters or leaves an object, substance, or region. - Synonyms: (conductors, anodes, cathodes)

You put two electrodes in a glass of water with some salt, turn on the power, and you get hydrogen and oxygen bubbles.

4. electrolyzers [ɪˈlɛktroʊˌlaɪzərz] - (noun) - Devices that use electricity to cause a chemical reaction, often used to decompose chemical compounds in the process known as electrolysis. - Synonyms: (separators, converters)

Conventional electrolyzers use electricity not just to create hydrogen molecules, but also to separate out unwanted oxygen molecules.

5. sequestered [sɪˈkwɛstərd] - (verb) - To isolate or hide away; in environmental terms, to capture and store carbon dioxide to prevent it from entering the atmosphere. - Synonyms: (isolated, concealed, segregated)

If we're successful, we're producing piles of black carbon that ultimately gets sequestered back into the ground.

6. hydrocarbon [ˈhaɪdroʊˌkɑrbən] - (noun) - An organic compound consisting entirely of hydrogen and carbon, commonly used to make fuels. - Synonyms: (organic compound, carbon-rich compound)

Natural gas is a hydrocarbon. It's made out of hydrogen and carbon.

7. decarbonize [diˈkɑrbəˌnaɪz] - (verb) - To reduce the amount of carbon emissions produced by something, typically in energy production or industrial processes. - Synonyms: (decarbonate, delaminate, desulfurize)

I want to see a decarbonized future.

8. flammable [ˈflæməbl] - (adjective) - Easily set on fire; able to burn quickly. - Synonyms: (combustible, incendiary, ignitable)

And since hydrogen is extremely flammable, safety is always a concern.

9. innovation [ˌɪnəˈveɪʃən] - (noun) - The process of making changes in something established, especially by introducing new methods, ideas, or products. - Synonyms: (invention, novelty, modernization)

Several startups, like H2Pro and CZero, are striving to innovate in the hydrogen production industry.

10. turquoise hydrogen [ˈtɜrkwɔɪz ˈhaɪdroʊʤən] - (noun) - A method of producing hydrogen that is low cost and low emission, generating solid carbon as a byproduct instead of CO2. - Synonyms: (hybrid hydrogen, efficient hydrogen, clean hydrogen)

We describe what we're doing at c zero as turquoise hydrogen, because it's kind of a combination both blue and green.

How Cheap Hydrogen Could Become the Next Clean Fuel

Hydrogen has a very special place in the universe. It's the first element on the periodic table. It is the most abundant element in the universe. And when clean energy advocates think about what can we find which would be as easy to use as fossil fuels, they think about hydrogen, the fuel that will, when burned, only produce water. We like to imagine that if we just built enough of these and these, we could ditch fossil fuels and save the planet. Unfortunately, it's not that simple. There are some things where you just need good, old fashioned combustible fuel.

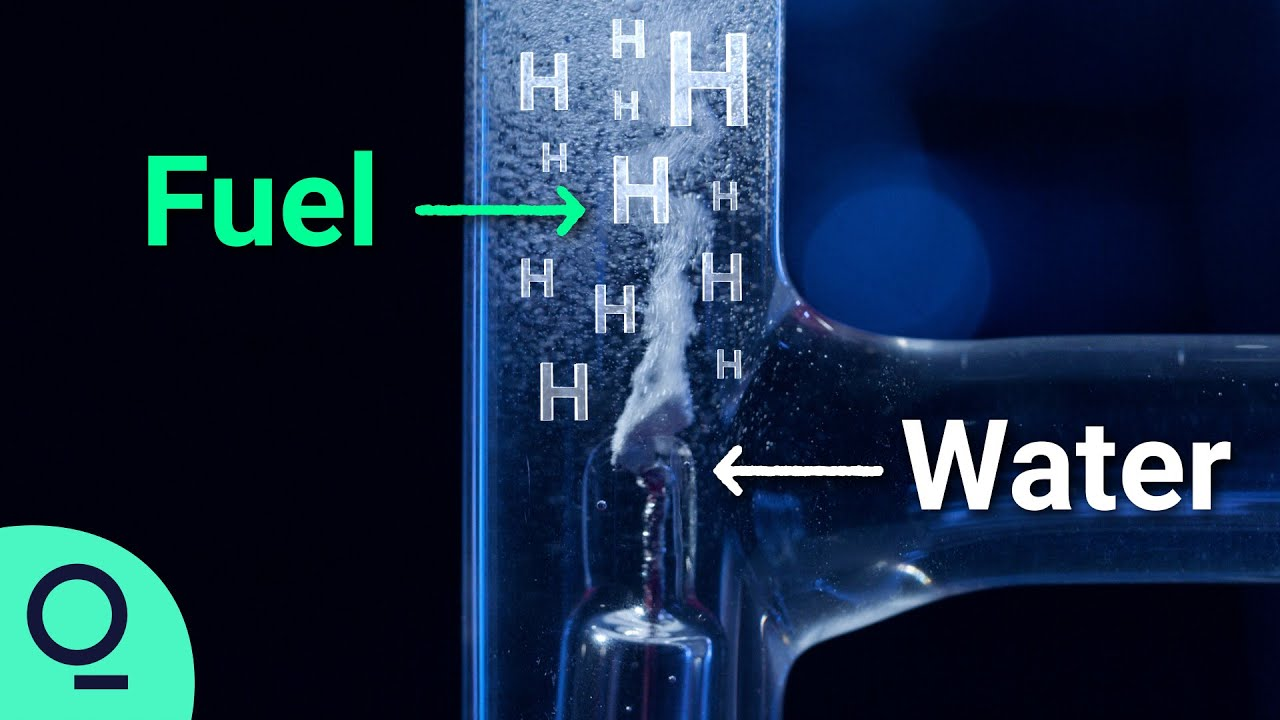

Now, startups around the world are betting that hydrogen can become the fuel of the 20 century. Just like today, we use fossil fuels for different applications, like power plants, cars and trucks, and trains. Hydrogen will be used for all this variety of different applications. Eventually, the world's going to have to care about CO2. As soon as you start to care about CO2, hydrogen becomes pretty interesting. But turning the most common element in the universe into the new fuel of choice is harder than it might seem. The first thing you need to know about hydrogen is that not all hydrogen is created equal. Allow us to introduce the hydrogen. Rainbow hydrogen is unique because you can generate it in many different ways. And the different ways in which it is created actually are defined by colors. The rainbow scales from the most environmentally friendly to the least. Gray hydrogen means taking natural gas and converting that into hydrogen, while creating CO2 emissions in the process. Blue hydrogen is gray hydrogen, but with carbon capture instead. So there are no CO2 emissions that are put into the atmosphere. Instead, they are captured and buried deep underground. There's also pink hydrogen, where you use nuclear power to create hydrogen. One color is prized above them all. Green. Green hydrogen is the hydrogen that everybody wants, because it's the hydrogen that uses renewable electricity to split water into hydrogen and oxygen.

If we could make enough green hydrogen, we'd have a clean fuel source with incredible versatility, making electricity whenever we need it, powering heavy industry, and theoretically, even replacing fossil fuels in some of the most polluting forms of transportation. Today, though, most hydrogen is produced on the polluting end of the spectrum. So engineers are working on getting green hydrogen up to speed. At h two pro, we're developing a new technology that splits water into hydrogen and oxygen. The environment was always dear to me. I remember as a kid having this poster in my room, the earth, and it was written on it, fragile, handled with care. And being here is a tremendous opportunity to actually do something about it. Thoman Marko founded and sold two app companies for more than a billion dollars before following his green dreams and starting H two pro in 2019. The process of splitting water has been known for over 200 years. You put two electrodes in a glass of water with some salt, turn on the power, and you get hydrogen and oxygen bubbles. Today, I was in my son's classroom, and I showed them an experiment of how we can split water very easily. I just took a nine volt battery, placed it in the water with some salt, and voila, you have hydrogen and oxygen coming out. That's nice, but it's very, very inefficient, and therefore very, very costly.

The hard thing is how to make hydrogen efficiently and with low cost. Our technology is different in the fact that it's more efficient and it's cheaper to manufacture, resulting in cheaper hydrogen for our customers. That's made possible by a fancy engineering trick. Conventional electrolyzers use electricity not just to create hydrogen molecules, but also to separate out unwanted oxygen molecules. H two pro found a way to separate the oxygen using heat. Instead, we have the oxygen being released just by raising the temperature. So we are releasing the oxygen without applying any power. This is the reason why we can be so much more efficient. This is the unique technology of H two Pro. These specific electrodes themselves, they release the oxygen.

The next level. When we're going to make our factory, it's going to work in a very similar approach. Like here. H two pro is fighting an uphill battle just by virtue of being green. Electrolysis makes up just 2% of hydrogen production today, and many investors didn't see the potential for growth. Initially, it was very, very difficult to raise money for H two Pro. In fact, we had to reach over 100 funds until we managed to get the company funded. Scaling is never easy. Our system produces 500,000 times more hydrogen than where we were three years ago. But we still have a ways to go. The ultimate test will be whether H two Pro can make its product cheaply enough to race ahead of its more established competition. The long term goal for hydrogen to become a viable fuel is for it to cost between a dollar or $2 a kilogram. We are nowhere close to that. We are probably in the three or four or $5 range for green hydrogen today. We anticipate that our customers will have a cost of about $1 per kilogram of green hydrogen by the end of this decade.

Companies like H two pro still have a long way to go before they're producing green hydrogen at scale. But being green isn't the only way to be green. That'll make sense in a minute. We describe what we're doing at c zero as turquoise hydrogen, because it's kind of a combination both blue and green, in that it's low cost and low emission. Czero has developed a technology for removing the carbon in natural gas. Natural gas is a hydrocarbon. It's made out of hydrogen and carbon. And what we do is remove the carbon. And so we pull out the solid carbon out of the hydrogen that we produce. And there are no direct CO2 emissions because anything that would have been CO2 is instead solid carbon.

If you want to get hydrogen from water, it takes seven and a half times as much energy to go pull hydrogen off of oxygen by splitting water as it does to pull hydrogen off of carbon through our process. The way c zero achieves it is using molten solids. It has a big chamber full of salt that is heated to a very high temperature. So this is an example of one of our laboratory scale reactors. So right here we have a very high temperature, around 1000 degrees and slightly above molten media column. And it bubbles natural gas through that chamber, leaving behind carbon in its elemental form. And hydrogen is a gas that can be trapped and sold. If we're successful, we're producing piles of black carbon that ultimately gets sequestered back into the ground. You can think of it almost as pre combustion carbon capture. Rather than ending up with CO2 that you have to concentrate, compress, put into a pipeline and inject it underground. We pull out ahead of time as a solid that's much denser and you can move around with conventional solids handling equipment and dispose of just like green hydrogen. The success of turquoise hydrogen will ultimately come down to cost $1.50 per kilogram of hydrogen is our target for doing this at very large scale. If you can be $2 a kilogram or less with very low to zero CO2 emissions, that's kind of a game changer.

The tough economics of hydrogen can make it sound like we're a long way from reaching the cleaner end of the rainbow. And it's true that companies like C Zero and H two Pro are going to have to make hydrogen at vastly larger scales before they can make a dent in fossil fuel consumption. But some industrial companies arent waiting for the economics to be perfect before making the switch. Even in one of the most polluting industries in the world, SCB is a steel company having production capacity of approximately 9 million tons of steel products per year. We alone account for for 10% of Sweden's total CO2 emission.

If we want to cut emission, we can't continue with the current blast furnace based technology. We need to change technology. So that's exactly what SSAB did. Developing a way of replacing coal with hydrogen in their steel making process. In the process of making steel, a factory has to convert iron ore into iron. Iron ore is iron plus oxygen. The removal of oxygen requires typically the use of coal, which will combine with oxygen to form CO2 and warm the planet. You could also use green hydrogen to take the oxygen away, and that will only produce water. Our aim is to decarbonize the whole value chain, from mining to ironmaking, steelmaking, but also deliver final product to our customers without using fossil fuel. That's the aim. We believe this is going to contribute not only cutting our own emissions, but this technology can also be used by others when they are ready to take this step.

It's not going to be easy for industries to take full advantage of hydrogen. Even when production costs come down, storing and transporting the stuff is something of a nightmare. And since hydrogen is extremely flammable, safety is always a concern. Just look at the hydrogen zeppelins of the early 20th century. But if we can overcome the economic and engineering challenges, the most abundant element in the universe could provide the abundant energy we need. I want to see a decarbonized future. But I'm also an engineer, a practicalist and a realist. And that transition to a low carbon future is not going to happen overnight. And we need realistic transition options and technologies that allow us to decarbonize our existing applications. I love this company, I love the people I work with. And we're all in this together for this almost sacred mission. This is our duty for our children, and for our grandchildren, and for generations to come.

Technology, Innovation, Science, Hydrogen, Clean Energy, Environmental Sustainability, Bloomberg Originals